English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

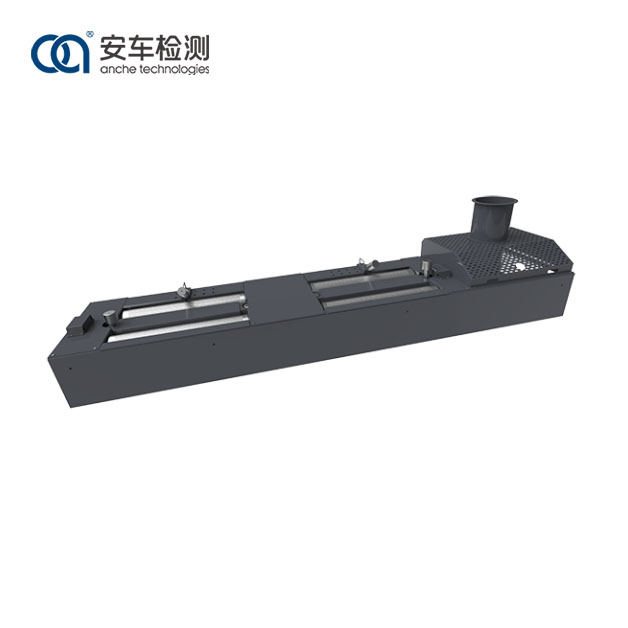

13-Ton Chassis Dynamometer

Send Inquiry

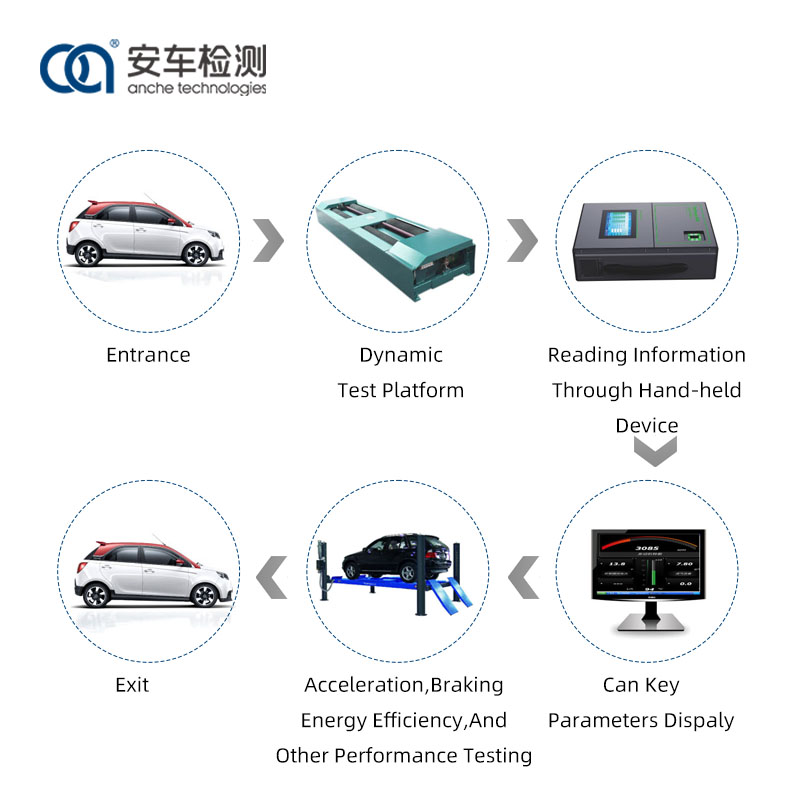

The chassis dynamometer is designed to measure the output power of the driving wheels of vehicles under rated torque, the output power of the driving wheels under rated power, the rolling resistance of the wheels under multiple speeds, as well as to test the resistance of the chassis transmission system, acceleration time, sliding distance and speed indication error of speedometer.

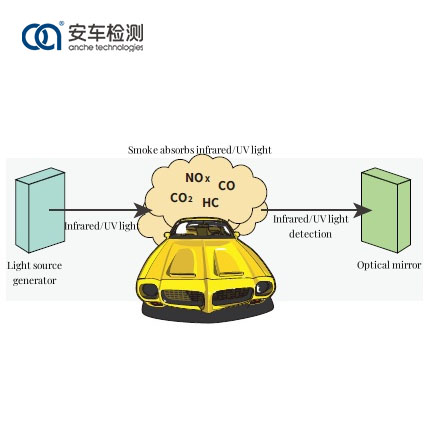

Working principle of 13-Ton Chassis Dynamometer

The driving wheels of the vehicle drive the main and auxiliary rollers to rotate. In the absence of slippage on the tire and roller surfaces, the linear speed on the roller surface is the driving speed of the vehicle. The speed sensor installed on the active roller outputs a pulse signal, and the pulse frequency is proportional to the roller speed.

The road resistance during driving is simulated by eddy current loading, and the translational inertia of the vehicle and the rotational inertia of non-driving wheels are simulated by the flywheel inertia system.

When the excitation current of the eddy current machine interacts with the rotating external magnetic field, a braking torque is generated, which reacts on the surface of the roller and acts on the S-shaped pressure sensor through the force arm. The output analog signal of the sensor is proportional to the magnitude of the braking torque.

According to relevant physical theorems, the power P can be calculated with the vehicle speed (speed) and traction force (torque).

Characteristics:

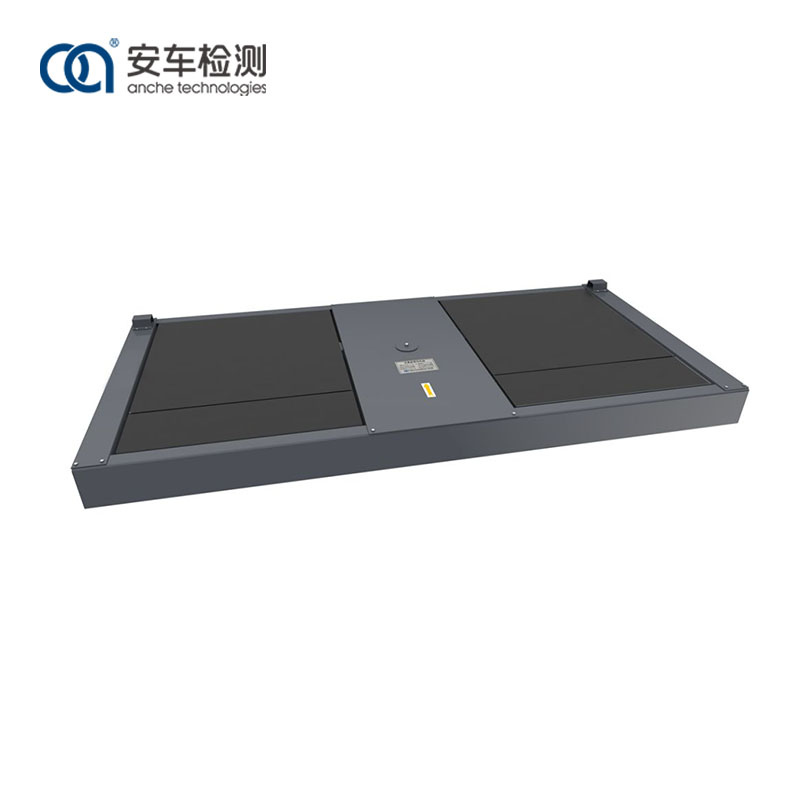

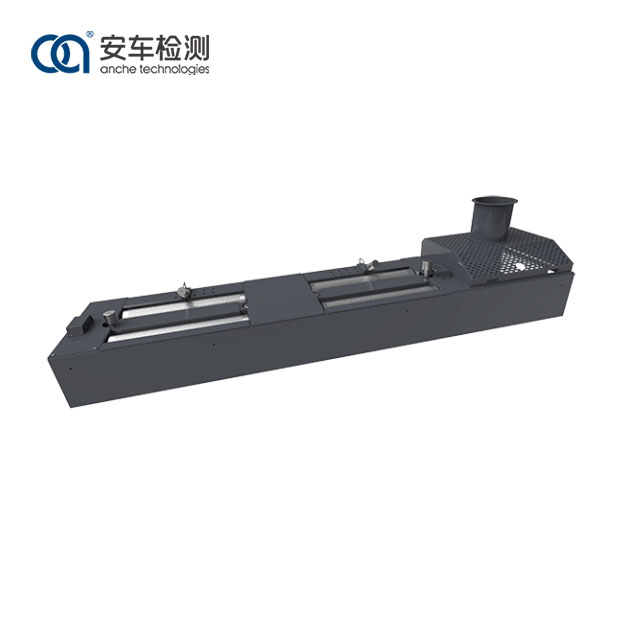

1. The 13-ton chassis dynamometer is welded with square steel pipes and high-quality carbon steel plates, with a sturdy structure and high strength.

2. The surface of the roller is treated with special technology, with high adhesion coefficient and good wear resistance;

3. A high-power air-cooled eddy current power absorption device is adopted, with superior performance and easy installation;

4. The measurement components use high-precision encoders and force sensors, which can obtain precise and accurate data;

5. The signal connection interface adopts an aviation plug design, which ensures fast and efficient installation and stable and reliable data;

6. The rollers are highly precise in dynamic balancing and runs smoothly.

Application of 13-Ton Chassis Dynamometer

Anche chassis dynamometer is designed and produced strictly in accordance with the Chinese national standards GB 18285 Limits and measurement methods for exhaust pollutants from gasoline vehicles under two-speed idle conditions and short driving mode conditions, GB 3847 Limits and measurement methods for emissions from diesel vehicles under free acceleration and lug down cycle, as well as HJ/T 290 Equipment specifications and quality control requirements for gasoline vehicles exhaust emission test in short transient loaded mode, HJ/T 291 Equipment specifications and quality control requirements for gasoline vehicles exhaust emission test in steady-state loaded mode, and JJ/F 1221 Calibration specification for chassis dynamometers for automotive emission testing. Anche chassis dynamometer is logical in design, sturdy and durable in its components, precise in measurement, simple in operation, comprehensive in its functions, and clear in display. The measurement results and guidance information can be displayed on the LED screen.

Anche chassis dynamometer is suitable for different industries and fields, and can be used in the automotive aftermarket for maintenance and diagnosis, as well as in motor vehicle test centers for vehicle inspection.

Parameters of 13-Ton Chassis Dynamometer

|

Model |

ACCG-13 |

|

|

Maximum Axle Load |

13,000kg |

|

|

Roller Size |

Φ373×1,150mm |

|

|

Maximum Speed |

130m/km |

|

|

Maximum Testable Traction |

2×10,000N |

|

|

Roller Dynamic Balance Accuracy |

≥G6.3 |

|

|

Machine Inertia |

1,452±18kg |

|

|

Working Environment |

Power Supply |

AC 380±38V/220±22V 50Hz±1Hz |

|

Temperature |

0 ℃ ~40 ℃ |

|

|

Relevant Humidity |

≤85%RH |

|

|

Boundary Dimensions ( L×W×H) |

4,400×2,400×550mm |

|