English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

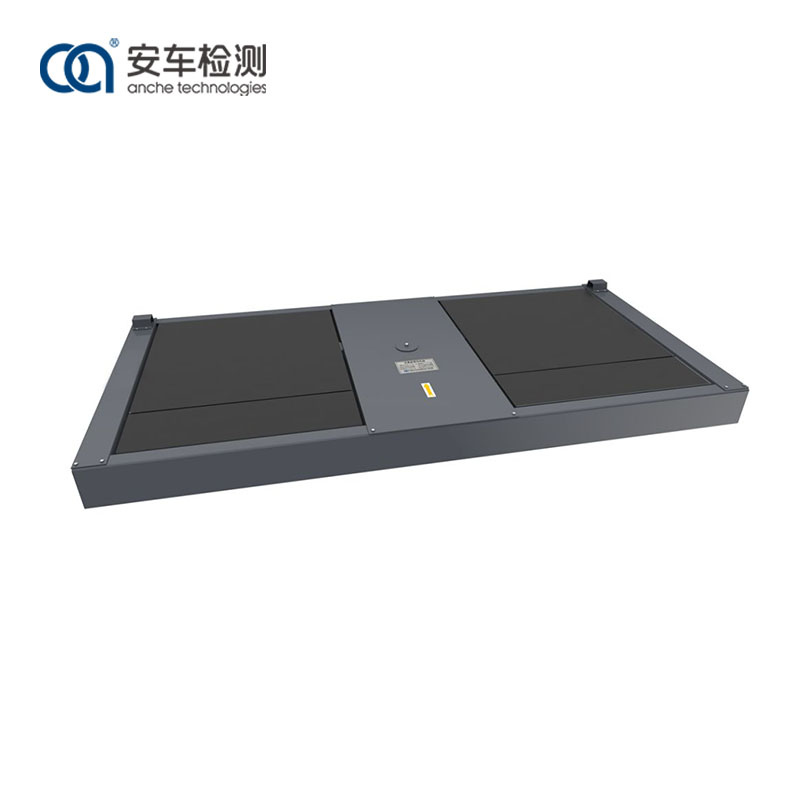

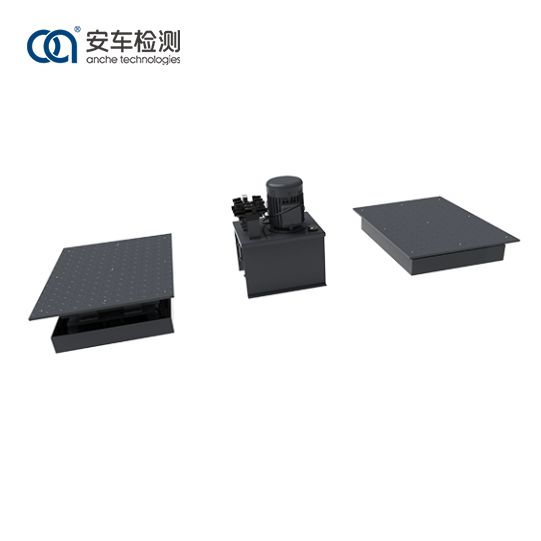

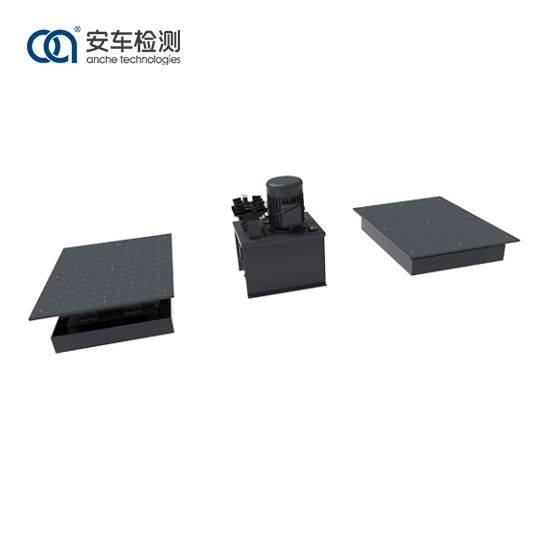

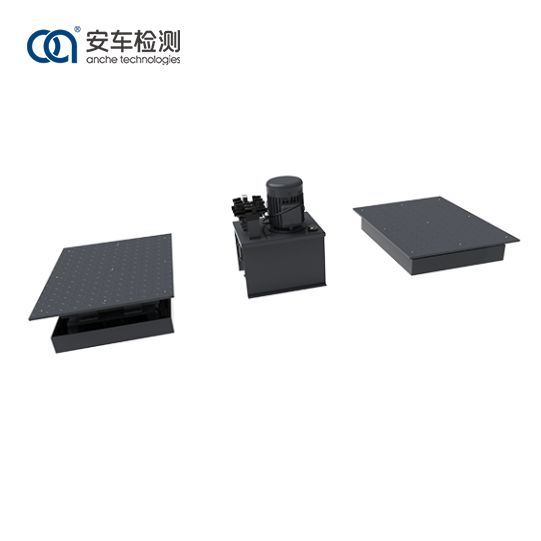

13-Ton Play Detector

Anche is a professional manufacturer of 13-ton play detectors, with a professional and strong R&D and design team that can customize the needs of different customers and we can offer better pricing and competent service. 13-ton play detector is an auxiliary device to manually check the clearance of vehicle suspension and steering system.

Send Inquiry

Working principle of 13-ton Play Detector:

The 13-ton play detector is installed inside the foundation, secured with cement mortar, and the surface of the plate is level with the ground. The steering system of the vehicle remains on the plate. The inspector operates the control handle in the pit, and the plate can move smoothly left and right or back and forth under the action of hydraulic pressure, for the purpose of observation and gap determination by the inspector.

Characteristics of 13-ton Play Detector:

1. It is welded with square steel pipes and high-quality carbon steel plates, with a sturdy structure, high strength, and resistance to rolling.

2. It adopts hydraulic drive control technology for smooth operation.

3. The signal connection interface adopts an aviation plug design, which is fast and efficient for installation, and the signal is stable and reliable.

4. The play detector has strong compatibility and is compatible with different vehicle models for measurement.

Eight directions: left and right plates can both move forward, backward, left and right.

Six directions: left plate can move forward, backward, left and right, and right plate can move forward and backward.

Application of 13-ton Play Detector

Anche play detector is strictly designed and produced in accordance with the Chinese national standard JT/T 633 Automotive suspension and steering clearance tester and is logical in design and sturdy and durable in components, precise in measurement, simple in operation and comprehensive in functions.

Play detector is suitable for different industries and fields, and can be used in the automotive aftermarket for maintenance and diagnosis, as well as in motor vehicle test centers for vehicle inspection.

Parameters of 13-ton Play Detector

|

Model |

ACJX-13 |

|

Allowable shaft mass (kg) |

13,000 |

|

Maximum displacement of table panel (mm) |

100×100 |

|

Maximum displacement force of table panel (N) |

>20,000 |

|

Sliding plate moving speed (mm/s) |

60-80 |

|

Table panel size (mm) |

1,000×750 |

|

Driving form |

Hydraulic |

|

Supply voltage |

AC380V±10% |

|

Motor power (kw) |

2.2 |

Details