English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

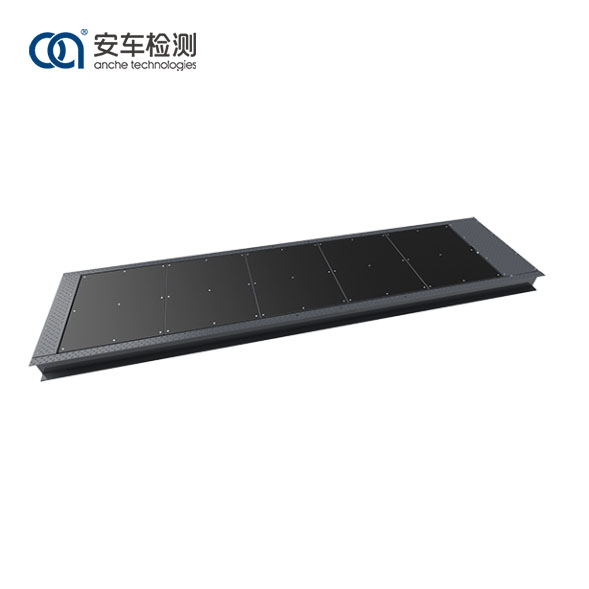

3-Ton Plate Brake Tester

Anche is a professional manufacturer of plate brake testers for vehicles, with a strong R&D and design team that can customize the needs of different customers. 3-ton plate brake tester is one tonnage of our plate brake testers, we also manufacture other tonnages. Anche plate brake tester can test the maximum braking force, dynamic and static axle load, and maximum braking difference between left and right wheels of the vehicle in motion.

Send Inquiry

Anche plate brake tester can test the braking force and axle load (optional) of the vehicles, thus evaluating braking performance of the vehicle. The tester can test the braking performance of vehicles with lower chassis and ABS device, and can truly simulate the braking characteristics of the vehicles on real road. During the testing process, the forward tilt of the vehicle can be fully reflected, making the measurement results more in line with the road test conditions.

Working principle:

Measurement principle of wheel load:

The wheels press against the load-bearing plate, and the wheel load causes elastic deformation of the sensor strain bridge. The strain bridge becomes unbalanced, and the bridge outputs an unbalanced voltage. The voltage is linearly related to the deformation of the strain bridge, and the deformation of the bridge is also linearly related to the gravity it receives. The control system converts the collected electrical signals into wheel load signals to measure the wheel load.

Measurement principle of braking force:

When the vehicle runs on the brake tester and the brakes are applied forcefully, the friction between the wheels and the plate causes the load-bearing plate to generate a tension force on the braking force sensor. The sensor strain bridge undergoes elastic deformation, and the strain bridge becomes unbalanced, outputting an unbalanced voltage. This voltage is linearly related to the deformation of the strain bridge, and the deformation of the bridge is also linearly related to the braking friction force it receives. The control system converts the collected electrical signals into braking force signals based on this characteristic to measure the braking force.

Characteristics of 3-Ton Plate Brake Tester:

1. It is welded from a solid square steel pipe and carbon steel plate structure, with a sturdy structure, high strength, and beautiful appearance.

2. The tester plate adopts a special corundum process, with high adhesion coefficient and long service life.

3. The measurement components use high-precision force and wheel load sensors, which can obtain precise and accurate data.

4. The signal connection interface adopts an aviation plug design, which ensures fast and efficient installation and stable and reliable data.

5. The brake tester has strong compatibility and can be compatible with different vehicle models.

Application

Anche 3-Ton plate brake tester is designed and manufactured strictly in accordance with the Chinese national standards GB/T28529 Platform brake tester and JJG/1020 Platform brake tester. It is logical in design, sturdy and durable in its components, precise in measurement, simple in operation, comprehensive in functions and clear in display. The measurement results and guidance information can be displayed on the LED screen.

Anche 3-Ton plate brake tester is suitable for different industries and fields, and can be used for maintenance and diagnosis in the automotive aftermarket, as well as for vehicle inspection at test centers.

Parameters:

|

Model |

ACPB-3 |

|

Allowable axle load mass (kg) |

3,000 |

|

Wheel braking force test range (daN) |

0-1,500 |

|

Measurable wheelbase range (m) |

1.6-5.2 |

|

Measuring speed (km) |

5-10 |

|

Indication error: wheel weight |

±2% |

|

Indication error: braking force |

±3% |

|

Corundum adhesioncoefficient |

0.85 |

|

Single panel size (L×W) mm |

800×1,000 |

Details